ADSS 6F 80M SPAN SM G652D Single Jacket

Single-jacket ADSS cable with G.652.D SM fiber, 50-150m max span.

-40°C to +70°C operating temp, 110kv max applied voltage.

Low attenuation: ≤0.36dB/km@1310nm, ≤0.22dB/km@1550nm.

FRP central strength + Aramid yarns for robust mechanical performance.

Water-blocking design, compliant with IEC 60794, ITU-T standards.

6-288 fiber counts, customizable OEM structural options.

- Product Description

- Specification

- Product Advantage

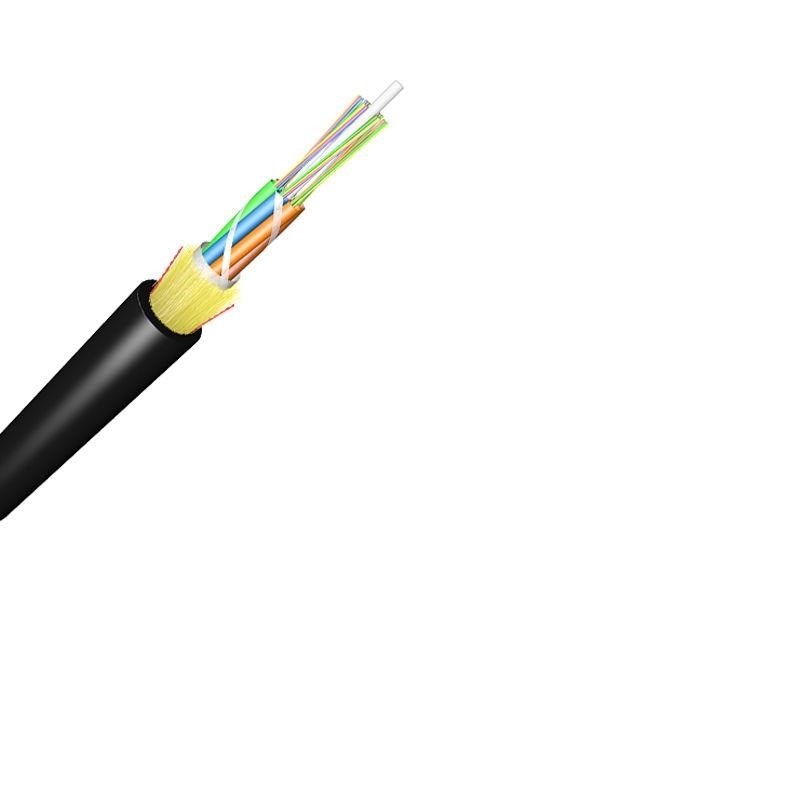

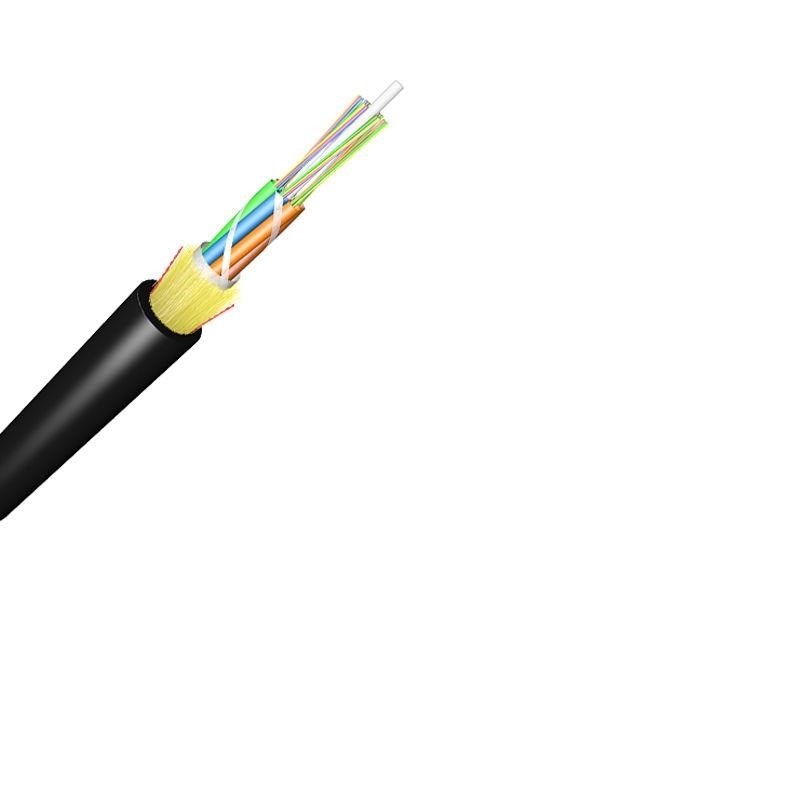

Product Description

1. Product Overview

This product is an All-Dielectric Self-Supporting (ADSS) optical fiber cable with a single jacket structure. It is designed for reliable optical signal transmission in various environments, supporting different fiber counts and spanning requirements. The cable complies with multiple international and industry standards to ensure stable performance and compatibility.

2. Standards Compliance

• ITU-T Rec. G.657A

• ISO9001

• IEC 60794

• ICEA-596

• GR-409

• YD/T 1997-2009

• EIA/TIA 598B (for fiber and binder color coding)

Specification

3. Optical Characteristics

3.1 Fiber Types

• G.652.D (single-mode)

• G.655 (single-mode)

• 50/125μm Multimode

• 62.5/125μm Multimode

3.2 Attenuation

Wavelength | Fiber Type | Attenuation (≤ dB/km) |

850nm | 50/125μm Multimode | 3.0 |

850nm | 62.5/125μm Multimode | 3.0 |

1300nm | 50/125μm Multimode | 1.0 |

1300nm | 62.5/125μm Multimode | 1.0 |

1310nm | G.652.D | 0.36 |

1310nm | G.655 | 0.40 |

1550nm | G.652.D | 0.22 |

1550nm | G.655 | 0.23 |

1285-1330nm | All fibers | 0.37 |

1383nm | G.652.D (Normal & Best) | 0.30 |

1383nm | G.657.A1 & G.657.A2 | 0.31 |

1490nm | G.652.D (Best) | 0.23 |

1490nm | G.657.A1 & G.657.A2 | 0.23 |

1490nm | G.652.D (Normal) | 0.24 |

1525-1575nm | G.652.D (Normal) | 0.22 |

1525-1575nm | G.652.D (Best) | 0.21 |

1525-1575nm | G.657.A1 & G.657.A2 | 0.21 |

1625nm | G.652.D (Normal) | 0.25 |

1625nm | G.652.D (Best) | 0.24 |

1625nm | G.657.A1 & G.657.A2 | 0.22 |

3.3 Bandwidth

Wavelength | Fiber Type | Bandwidth (≥ MHz·km) |

850nm | 50/125μm Multimode | 500 |

850nm | 62.5/125μm Multimode | 200 |

1300nm | 50/125μm Multimode | 1000 |

1300nm | 62.5/125μm Multimode | 600 |

3.4 Polarization Mode Dispersion (PMD)

• Individual fiber (G.652.D, G.655): ≤ 0.20 ps/√km

• Design Link Value (M=20, Q=0.01%) (G.652.D, G.655): ≤ 0.10 ps/√km

• Maximum Individual Fiber (all types): ≤ 0.1 ps/√km

• Link Design Value (all types): ≤ 0.06 ps/√km

3.5 Mode Field Diameter (MFD)

Wavelength | Fiber Type | MFD (μm) |

1310nm | G.652.D (Normal) | 8.6 ± 0.4 |

1310nm | G.652.D (Best) | 9.0 ± 0.4 |

1310nm | G.657.A1 | 9.0 ± 0.3 |

1310nm | G.657.A2 | 8.6 ± 0.4 |

1550nm | G.652.D (Normal) | 9.8 ± 0.5 |

1550nm | G.652.D (Best) | 10.2 ± 0.4 |

1550nm | G.657.A1 | 10.2 ± 0.4 |

1550nm | G.657.A2 | 9.6 ± 0.5 |

3.6 Zero Dispersion Wavelength & Dispersion Coefficient

• Zero Dispersion Wavelength: 1300-1324 nm (all variants)

• Dispersion Coefficient (1285-1339 nm): ≤ 3.4 ps/(nm·km) (G.652.D, G.657.A1 & A2)

3.7 Bending Loss

Wavelength | Bending Condition | Loss (≤ dB) |

1550nm | 15mm radius, 10 turns | 0.25 |

1550nm | 25mm radius, 100 turns | 0.03 |

1550nm | 10mm radius, 1 turn | 0.75 |

1550nm | 7.5mm radius, 1 turn | 0.2 |

1550nm | 30mm radius, 100 turns | 0.05 |

1625nm | 15mm radius, 10 turns | 1.0 |

1625nm | 10mm radius, 1 turn | 1.5 |

1625nm | 7.5mm radius, 1 turn | 0.5 |

3.8 Point Discontinuity

• At 1310 nm & 1550 nm: ≤ 0.05 dB (all fibers)

4. Structural Specifications

4.1 Core Components

• Fiber Optic: UV fiber G.652.D; @1310nm ≤0.35dB/km; @1550nm ≤0.2dB/km

• Tube Filling Compound: Water Blocking & Moisture Proof Thyrotrophic gel

• Loose Tube: 1.8-2.0 mm PBT; outer diameter options: 1.8, 2.0, 2.5 mm (adjustable for OEM: 1.5|2.0, 1.8|2.3, 2.1|2.3 mm)

• Filler: 1.8 mm LDPE / PP (FRP filler)

• Center Strength Member: Glass Fiber Reinforced Plastic Rod (GFRP); diameter options: 2.0, 2.5, 2.8, 3.7 mm (adjustable for OEM: 1.8|2.3, 1.8|2.3, 2.5, 2.8, 3.7, 2.6 mm); PE coated optional

• Water Blocking Layer: 0.28mm thickness water blocking tape + 2*Water Blocking Yarn

• Binder: 2 wires Polyester Yarns

• Ripcords: 2 wires

• Dielectric Strength Members: Aramid Yarns KEVLAR K49-3000D

• Inner Jacket: 0.9-1.0mm thickness HDPE / MDPE

• Outer Jacket: 1.6-2.0mm thickness HDPE / MDPE; standard thickness 1.8mm (1.5-2.0mm for OEM); color: Black

4.2 Fiber Count & Loose Tube Configuration

Fiber Count | Tubes per Fiber Count | Cable Diameter (Approx., mm) | Cable Weight (Typical, kg/km) |

6 | 1x6, 2x6, 4x6 | 9.5 (adjustable: 8.0 | 8.5 |

12 | 4x12, 6x12, 8x12, 12x12 | 9.5 | 10 (adjustable: 8.0 |

24 | 24x12 | 12.2 (adjustable: 8.0 | 8.5 |

48 | - | 13.9 | - |

72 | - | 17.1 | - |

96 | - | 20.2 | - |

120 | - | 13 (OEM) | 95 (OEM) |

144 | - | 13 (OEM) | 95 (OEM) |

288 | - | - | - |

4.3 OEM Structure Options

• Number of Cores: 12, 24, 48, 96, 120, 144 cores

• Design (Tube + Filler + Strength Member): 3+2+1 (12-core); 1+4+1 (24-core, 48-core, etc.)

• Central Strength Member Material: FRP (Fiber Reinforced Plastic) | Steel Wire; diameter (±0.05mm): 1.2mm | 1.0mm

• Other Strength Member: Aramid Yarns

• Loose Tube Diameter (±0.05mm): 2.1mm | 1.8mm

• Filler Diameter (±0.05mm): 1.8mm (PP material)

• Outer Sheath Thickness (±0.1mm): 0.8mm (smaller cores); 1.6mm, 1.9mm (larger cores)

5. Mechanical Characteristics

• Fiber Strain: ≥ 1%

• Fiber Load: ≥ 9 N

• Stress: ≥ 100 kpsi

• Dynamic Stress Corrosion Susceptibility Factor: ≥ 20 (Unaged & Aged: 30 days @ 85°C, 85% R.H.)

• Coating Strip Force (Peak Value): 1.3 - 8.9 N

• Fiber Curl: ≥ 4 m

• Max. Installation Tension: 2400 N (all core configurations)

• Min. Bending Radius: Without Tension - 10.0 x Cable Diameter; Under Maximum Tension - 20.0 x Cable Diameter

5.1 Mechanical Tests

Test Item | Test Method | Acceptance Requirements |

Tensile Strength | Apply 5000 N load over 50m cable length (IEC 794-1-E1) | Loss change ≤0.1 dB at 1550nm; no fiber break or sheath damage |

Crush Test | Apply 3000 N load over 100mm cable for ≥1 minute (IEC 60794-1-E3) | Loss change ≤0.1 dB at 1550nm; no fiber break or sheath damage |

Impact Test | 5 impact points, 5 times per point; impact energy 4.5 Nm; hammerhead radius 12.5mm; impact rate 2s/cycle (IEC 60794-1-E4) | Loss change ≤0.1 dB at 1550nm; no fiber break or sheath damage |

Repeated Bending | Bending diameter 20x cable OD; 250 N load; flexing rate 3s/cycle for 30 cycles (IEC 60794-1-E6) | Loss change ≤0.1 dB at 1550nm; no fiber break or sheath damage |

Torsion | 1m length; 150 N load; twist rate 1min/cycle; twist angle ±90°; 10 cycles (IEC 60794-1-E7) | Loss change ≤0.1 dB at 1550nm; no fiber break or sheath damage |

Compound Flow | 30cm sample; 70°C ±2°C; 24 hours (IEC 60794-1-E14) | No compound flow |

Sheath High Voltage Test | Online test with 9 kV voltage (dependent on sheath thickness) | No sheath breakdown |

6. Environmental Characteristics

6.1 Temperature Range

• Operating: -40°C to +70°C

• Installation: -20°C to +60°C (OEM)

• Transport & Storage: -40°C to +70°C (OEM)

6.2 Environmental Tests

Test Item | Test Method | Acceptance Requirements |

Dry Heat Aging | 30 days @ 85°C | Attenuation change ≤0.05 dB/km @1310nm & 1550nm |

Accelerated Aging | 30 days @ 85°C, 85% R.H. | Attenuation change ≤0.05 dB/km @1310nm & 1550nm |

Temperature Cycling | Temperature steps: +20°C → -20°C → +20°C → +40°C; 24h per step; 2 cycles (IEC 60794-1-F1) | Loss change ≤0.1 dB at 1550nm; no fiber break or sheath damage; attenuation change ≤0.05 dB/km @1310nm & 1550nm |

Water Soak | 30 days @ 23°C | Attenuation change ≤0.05 dB/km @1310nm & 1550nm |

Water Penetration | Submerge 3m sample in 1m water for 24 hours (IEC 60794-1-F5B) | No water leakage from opposite end |

6.3 Climate Conditions

• Maximum Wind Speed: 25m/s

• Ice Load: 0mm (no ice formation considered in design)

• Maximum Span Options: 50m, 80m, 100m, 120m, 150m (span needs recalculation for other climate conditions)

• Max Applied Voltage: 110kv

• MAT (Mechanical Test): 2100N (for 80m span); customizable per customer requirements

7. Cable Marking & Fiber Colors

7.1 Sheath Marking

• Content: [Cable type] [N*cores] G.652D [Manufacture year] [Length]m

• Marking interval: Every 1 meter

• Color: White

• Notes: Occasional unclear length marking permitted if neighboring markings are clear; both cable ends sealed with heat shrinkable end caps to prevent water ingress; customizable per client requirements

7.2 Fiber & Binder Color Code (EIA/TIA 598B)

No. | Color | No. | Color | No. | Color | No. | Color |

1 | Blue | 4 | Gray | 7 | Black | 10 | Green |

2 | Orange | 5 | Red | 8 | Yellow | 11 | Aqua |

3 | Brown | 6 | White | 9 | Violet | 12 | Pink |

8. Packaging & Delivery

8.1 Packaging

• Each cable length is reeled on wooden spools (Φ1100*750mm) suitable for long-distance shipment

• Covered by plastic buffer sheet and sealed by strong wooden battens

• At least 1m of inside end reserved for testing

• Standard spool length: 2000-4000m; 3km/spool or 4km/spool (2% tolerance allowed); single length not less than 96% of standard length per drum (for ≤10% of total supply); total quantity meets or exceeds ordered quantity

8.2 Drum Marking

• Content: "FIBER OPTICAL CABLE", Origin ("MADE IN CHINA"), Product name, Cable type and size, Drum length, Gross/Net weight (kg), Drum number, Manufacturing year and month, Loading/unloading/conveyance caution plate, Optional customer information (contract no., project no., delivery destination)

8.3 Delivery Specifications

• Minimum Order Quantity (MOQ): 100km

• Delivery Time: 5-25 Days

• Port of Loading: NINGBO CHINA

• Term of Payment: 30% TT as deposit, 70% Balance before shipping

9. Customization

• Other fiber counts, structures, cable diameters, and weights available per customer requirements

• OEM services offered for structural parameters (fiber count, loose tube diameter, central strength member, outer sheath thickness, etc.)

Mechanical test (MAT) customizable per specific customer requirements

Product Advantage

-

1

Superior optical performance with ultra-low attenuation (≤0.22dB/km@1550nm) for long-distance, high-fidelity signal transmission.

-

2

Robust all-dielectric structure (FRP + Aramid yarns) ensures excellent mechanical strength and resistance to harsh external stresses.

-

3

Wide operating temperature range (-40°C to +70°C) and 25m/s wind resistance, adapting to diverse environmental conditions.

-

4

Advanced water-blocking system (tape + yarn) and moisture-proof gel prevent water ingress, enhancing long-term reliability.

-

5

Flexible customization: 6-288 fiber counts, adjustable span (50-150m) and structural parameters to meet specific project needs.

-

6

Compliance with international standards (IEC 60794, ITU-T G.652.D) guarantees compatibility and quality consistency.

Home

Home