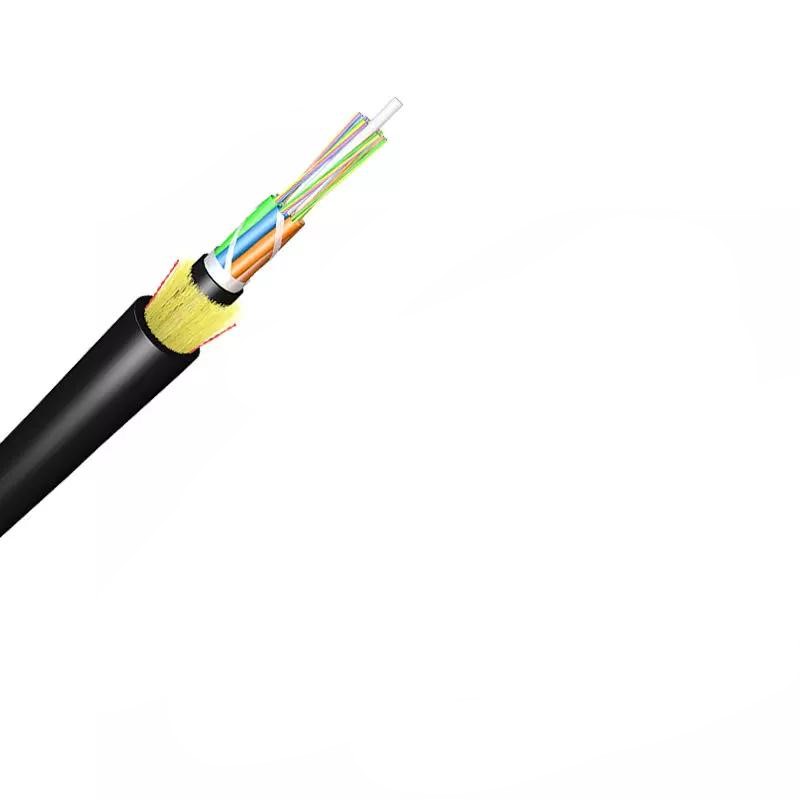

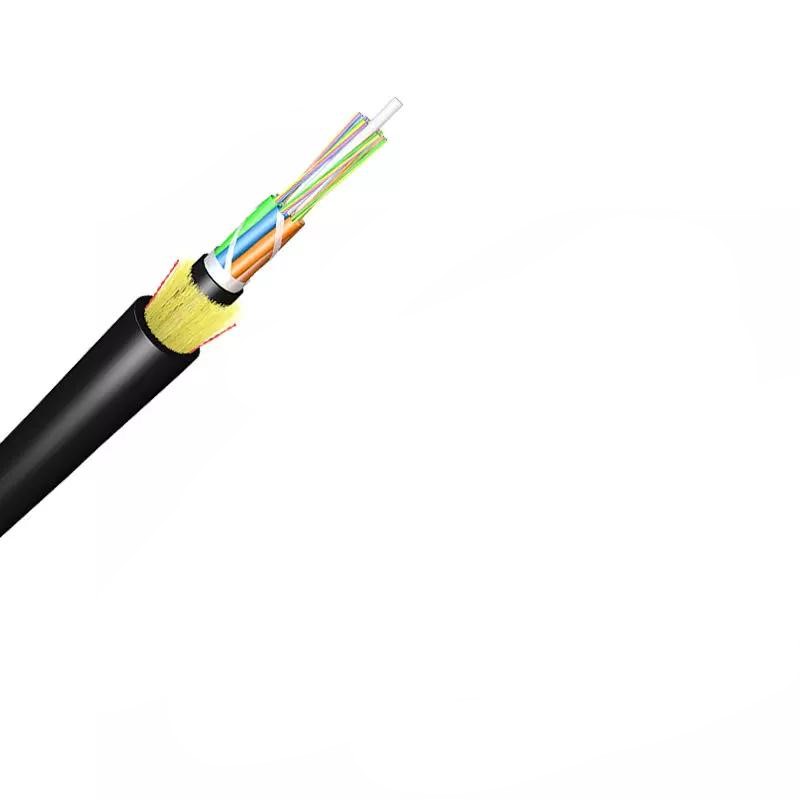

ADSS 24F 80M SPAN SM G652D Single Jacket

This single-sheath ADSS optical cable (G.652.D single-mode) supports 6-288 fibers, with max span 80m (up to 150m optional) and 110kv voltage. It features GFRP central strength member, Aramid yarn reinforcement, and HDPE/MDPE jackets for durability. Operating at -40°C to +70°C, it resists water, wind (25m/s), and mechanical stress. Compliant with ITU-T, IEC standards, it offers low attenuation (≤0.22dB/km @1550nm) and reliable transmission, customizable for OEM needs.

- Product Description

- Specification

- Product Advantage

Product Description

1. General Information

• Type: ADSS-Single Sheath

• Certifications: ISO9001

• Length per Spool: 3km or 4km (2% tolerance allowed)

• Packing: Wooden Spool (Φ1100*750mm)

• MOQ: 100km

• Delivery Time: 5-25 Days

• Port of Loading: NINGBO CHINA

• Payment Term: 30% TT as deposit, 70% Balance before shipping

2. Optical Fiber Specifications

2.1 Fiber Types

• G.652.D (single-mode)

• G.655 (single-mode)

• 50/125μm Multimode

• 62.5/125μm Multimode

2.2 Transmission Characteristics

Wavelength | Attenuation | Bandwidth |

850nm | 50/125μm: ≤3.0 dB/km; 62.5/125μm: ≤3.0 dB/km | 50/125μm: ≥500 MHz·km; 62.5/125μm: ≥200 MHz·km |

1300nm | 50/125μm: ≤1.0 dB/km; 62.5/125μm: ≤1.0 dB/km | 50/125μm: ≥1000 MHz·km; 62.5/125μm: ≥600 MHz·km |

1310nm | G.652.D: ≤0.36 dB/km; G.655: ≤0.40 dB/km | - |

1550nm | G.652.D: ≤0.22 dB/km; G.655: ≤0.23 dB/km | - |

2.3 Polarization Mode Dispersion (PMD)

• Individual Fiber: G.652.D/G.655 ≤0.20 ps/√km

• Design Link Value (M=20, Q=0.01%): G.652.D/G.655 ≤0.10 ps/√km

2.4 Mode Field Diameter (MFD)

• 1310nm: G.652.D Normal (8.6±0.4μm); G.652.D Best (9.0±0.4μm); G.657.A1 (9.0±0.3μm); G.657.A2 (8.6±0.4μm)

• 1550nm: G.652.D Normal (9.8±0.5μm); G.652.D Best (10.2±0.4μm); G.657.A2 (9.6±0.5μm)

2.5 Point Discontinuity

• At 1310nm & 1550nm: ≤0.05 dB

Specification

3. Cable Structure

3.1 Core Components

• Fiber Optic: UV fiber G.652.D; @1310nm ≤0.35dB/km; @1550nm ≤0.2dB/km

• Tube Filling Compound: Water Blocking & Moisture Proof Thyrotrophic gel

• Loose Tube: 1.8-2.0mm PBT; Outer diameter options: 1.8/2.0/2.5mm (adjustable: 1.5|2.0, 1.8|2.3, 2.1|2.3mm)

• Filler: 1.8mm LDPE/PP (FRP)

• Central Strength Member: 1.8mm GFRP; Diameter options: 2.0/2.5/2.8/3.7mm (adjustable: 1.8|2.3, 2.5, 2.8, 3.7, 2.6mm); PE coated optional

• Water Blocking Layer: 0.28mm thick water blocking tape + 2 water blocking yarns

• Binder: 2 wires Polyester Yarns

• Ripcords: 2 wires

• Dielectric Strength Members: Aramid Yarns KEVLAR K49-3000D

• Inner Jacket: 0.9-1.0mm thick HDPE/MDPE

• Outer Jacket: 1.6-2.0mm thick HDPE/MDPE; Standard thickness 1.8mm (1.5-2.0mm for OEM)

3.2 Cable Dimensions & Weight

• Cable Outer Diameter: 10.7±0.5mm (adjustable: 8.0|8.5|9.0|10.5|11.0mm)

○ 6 fibers: 9.5mm

○ 12 fibers: 9.5mm|10mm

○ 24 fibers: 12.2mm

○ 48 fibers: 13.9mm

○ 72 fibers: 17.1mm

○ 96 fibers: 20.2mm

• Cable Weight: 85±5kg/km

○ 12-core: 75kg/km

○ 24-core & larger: 95kg/km

3.3 Fiber Count & Loose Tube Configuration

Fiber Count | Tube Configuration |

6 | 1x6, 2x6, 4x6 |

8 | 6x8 |

12 | 4x12, 6x12, 8x12, 12x12 |

24 | 24x12 |

48/72/96/144/288 | Customizable |

4. Mechanical Characteristics

• Fiber Strain: ≥1%

• Fiber Load: ≥9N

• Stress: ≥100kpsi

• Dynamic Stress Corrosion Susceptibility Factor: ≥20 (unaged & aged: 30 days @85°C, 85% R.H.)

• Coating Strip Force (Peak Value): 1.3-8.9N

• Fiber Curl: ≥4m

• Max Installation Tension: 2400N (all core configurations)

• Min Bending Radius: Without tension (10x cable diameter); Under max tension (20x cable diameter)

• Max Span: 50m/80m/100m/120m/150m (80m standard for 24F model)

• MAT (Mechanical Test): 2100N

4.1 Mechanical Tests

Test Item | Method | Acceptance Requirement |

Tensile Strength | 5000N load over 50m cable | ≤0.1dB loss @1550nm; No fiber break/sheath damage |

Crush Test | 3000N load over 100mm for ≥1min | ≤0.1dB loss @1550nm; No fiber break/sheath damage |

Impact Test | 5 points, 5 times/point; 4.5Nm energy | ≤0.1dB loss @1550nm; No fiber break/sheath damage |

Repeated Bending | 20x OD bending diameter; 250N load; 30 cycles | ≤0.1dB loss @1550nm; No fiber break/sheath damage |

Torsion | 1m length; 150N load; ±90° twist; 10 cycles | ≤0.1dB loss @1550nm; No fiber break/sheath damage |

5. Environmental Characteristics

• Temperature Range:

○ Operation: -40°C to +70°C

○ Installation: -20°C to +60°C

○ Transport & Storage: -40°C to +70°C

• Weather Conditions: 25m/s wind speed + 0mm Ice Load

• Max Applied Voltage: 110kv

5.1 Environmental Tests

Test Item | Condition | Attenuation Requirement |

Dry Heat Aging | 30 days @85°C | ≤0.05dB/km (@1310/1550nm) |

Accelerated Aging | 30 days @85°C, 85% R.H. | ≤0.05dB/km (@1310/1550nm) |

Temperature Cycling | +20→-20→+20→+40°C; 2 cycles | ≤0.05dB/km (@1310/1550nm); No fiber break/sheath damage |

Water Soak | 30 days @23°C | ≤0.05dB/km (@1310/1550nm) |

Water Penetration | 3m sample in 1m water for 24h | No water leakage |

Compound Flow | 30cm sample @70±2°C for 24h | No compound flow |

Sheath High Voltage Test | Online test with 9kV (dependent on sheath thickness) | No sheath breakdown |

6. Standards Compliance

• ITU-T Rec. G.657A, G.652.D

• ISO9001

• IEC 60794

• ICEA-596

• GR-409

• YD/T 1997-2009

• EIA/TIA 598B (fiber/binder color code)

7. Marking & Color Code

7.1 Cable Marking

• Content: Cable name, N*cores, G.652D, manufacture year, length (meter)

• Interval: Every 1 meter

• Color: White

• End Sealing: Heat shrinkable end caps

7.2 Fiber Colors (12 Chromatography)

1. Blue

2. Orange

3. Brown

4. Gray

5. White

6. Red

7. Black

8. Yellow

9. Violet

10. Aqua

11. Pink

12. Green

8. OEM Customization

• Fiber count: 12/24/48/96/120/144 cores

• Structure design: 3+2+1 (12-core); 1+4+1 (24/48-core etc.)

• Central strength member: FRP/Steel Wire (1.2/1.0mm diameter)

• Outer sheath thickness: 0.8mm (smaller cores); 1.6/1.9mm (larger cores)

• Cable diameter: 9.0mm (12-core); 13mm (24-core & larger)

• Custom cable marking available

Note: Cable diameter and weight are typical values, subject to design variations. Span needs recalculation for specific regional climate conditions. Other structures and fiber counts available on request.

Product Advantage

-

1

Low attenuation for reliable long-distance transmission

-

2

Wide temp range (-40°C to +70°C) for harsh environments

-

3

Robust structure with GFRP & Aramid yarn reinforcement

-

4

Water/wind-resistant design (25m/s wind, 0mm ice load)

-

5

Compliant with global standards (ITU-T, IEC, ISO9001)

-

6

Flexible customization (fiber count, span, OEM options)

Home

Home