ADSS 12F 80M SPAN SM G652D Single Jacket

ISO9001-certified, compliant with international standards.

G.652.D single-mode fiber (G.655/multimode optional).

Max span 80m (up to 150m customizable), 110kv voltage rating.

Operating temp: -40°C to +70°C, withstands 25m/s winds.

GFRP central strength, Aramid reinforcement, water-blocking design.

6-288 fiber counts (OEM up to 144), ≤0.22dB/km attenuation at 1550nm.

Packaged on 3-4km wooden spools, customizable options available.

Excellent mechanical/environmental resistance, ideal for harsh-environment long-haul communications.

- Product Description

- Specification

- Product Advantage

Product Description

1. General Information

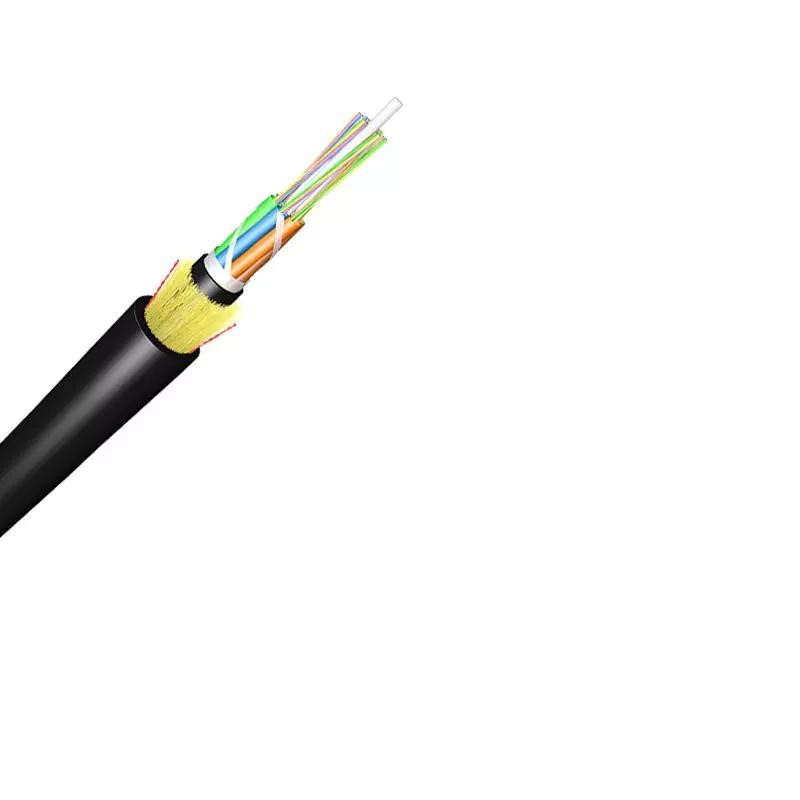

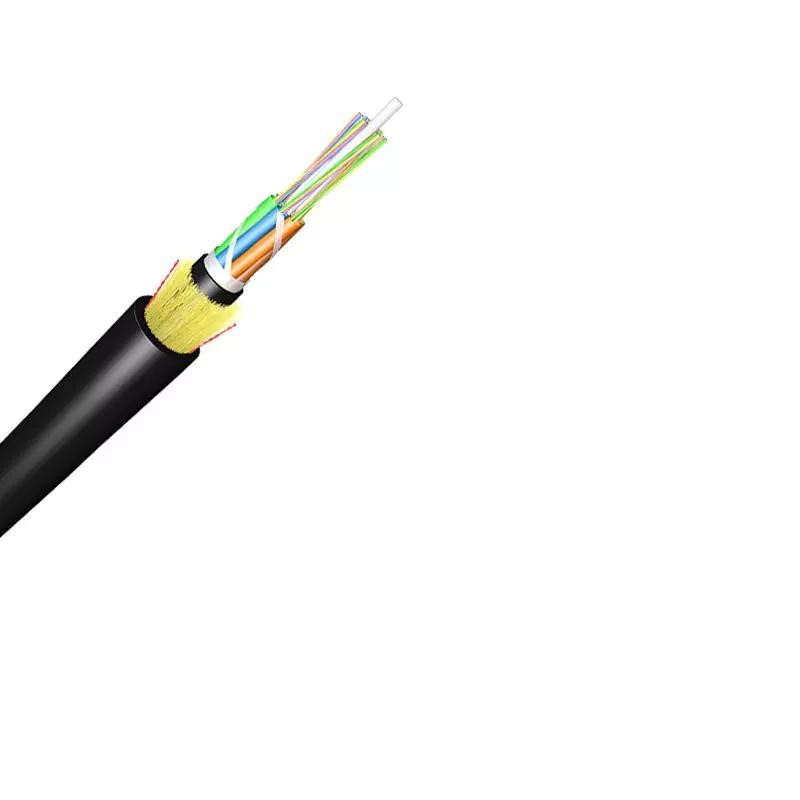

• Product Type: ADSS (All-Dielectric Self-Supporting) Single Jacket Optical Fiber Cable

• Certifications: ISO9001

• Length per Spool: 3km or 4km (with a tolerance of more than 2%)

• Packing: Wooden Spool (Φ1100*750mm)

• MOQ: 100km

• Delivery Time: 5-25 Days

• Port of Loading: NINGBO CHINA

• Payment Term: 30% TT as deposit, 70% Balance before shipping

2. Key Performance Parameters

• Max Span: 80m (MAT=2100N); Other options include 50m, 100m, 120m, 150m (span needs recalculation based on installation area's climate)

• Max Applied Voltage: 110kv

• Weather Conditions: 25m/s wind speed + 0mm Ice Load

• Temperature Range:

○ Operation: -40°C to +70°C

○ Installation: -20℃ to +60℃

○ Transport & Storage: -40℃ to +70℃

• Cable Outer Diameter: 10.7±0.5mm (adjustable for OEM: 8.0|8.5|9.0|10.5|11.0mm)

• Cable Weight: 85±5kg/km; 75kg/km (12-core), 95kg/km (24-core and larger configurations) (±10.0kg/km tolerance)

Specification

Component | Specification |

Fiber Optic | UV fiber G.652.D; Attenuation: @1310nm ≤0.35dB/km; @1550nm ≤0.2dB/km |

Tube Filling Compound | Water Blocking & Moisture Proof Thyrotrophic gel |

Loose Tube | 1.8-2.0mm PBT; Outer diameter options: 1.8, 2.0, 2.5mm (adjustable for OEM: 1.5 |

Filler | 1.8mm LDPE/PP (FRP) |

Center Strength Member | 1.8mm GFRP; Diameter options: 2.0, 2.5, 2.8, 3.7mm (adjustable for OEM: 1.8 |

Water Blocking Tape | 0.28mm thickness |

Binder | 2 wires Polyester Yarns |

Ripcords | 2 wires |

Dielectric Strength Members | Aramid Yarns KEVLAR K49-3000D |

Inner Jacket | 0.9-1.0mm thickness HDPE/MDPE |

Outer Jacket | 1.6-2.0mm thickness HDPE/MDPE; Standard thickness 1.8mm (1.5-2.0mm for OEM) |

4. Fiber Options & Optical Characteristics

4.1 Fiber Types

• Single-mode: G.652.D, G.655

• Multimode: 50/125μm, 62.5/125μm

• Fiber Count Options: 6, 12, 24, 48, 72, 96, 144, 288 fibers; OEM options: 12, 24, 48, 96, 120, 144 cores

4.2 Attenuation

Wavelength | Specification |

850nm | 50/125μm: ≤3.0dB/km; 62.5/125μm: ≤3.0dB/km |

1300nm | 50/125μm: ≤1.0dB/km; 62.5/125μm: ≤1.0dB/km |

1310nm | G.652.D: ≤0.36dB/km; G.655: ≤0.40dB/km; G.652.D Normal: ≤0.35dB/km; G.652.D Best: ≤0.34dB/km; G.657.A1/A2: ≤0.34dB/km |

1383nm | G.652.D (Normal/Best): ≤0.30dB/km; G.657.A1/A2: ≤0.31dB/km |

1490nm | G.652.D Best: ≤0.23dB/km; G.652.D Normal: ≤0.24dB/km; G.657.A1/A2: ≤0.23dB/km |

1550nm | G.652.D: ≤0.22dB/km; G.655: ≤0.23dB/km; G.652.D Best: ≤0.21dB/km; G.657.A1/A2: ≤0.20dB/km |

1525-1575nm | G.652.D (Normal/Best): ≤0.22dB/km (Normal), ≤0.21dB/km (Best); G.657.A1/A2: ≤0.21dB/km |

1625nm | G.652.D Normal: ≤0.25dB/km; G.652.D Best: ≤0.24dB/km; G.657.A1/A2: ≤0.22dB/km |

1285-1330nm | All fibers: ≤0.37dB/km |

4.3 Bandwidth

• 850nm: 50/125μm ≥500MHz·km; 62.5/125μm ≥200MHz·km

• 1300nm: 50/125μm ≥1000MHz·km; 62.5/125μm ≥600MHz·km

4.4 Polarization Mode Dispersion (PMD)

• Individual fiber: G.652.D/G.655 ≤0.20ps/√km; All fiber types ≤0.1ps/√km

• Design Link Value (M=20, Q=0.01%): G.652.D/G.655 ≤0.10ps/√km; All fiber types ≤0.06ps/√km

4.5 Mode Field Diameter (MFD)

Wavelength | Specification |

1310nm | G.652.D Normal: 8.6±0.4μm; G.652.D Best:9.0±0.4μm; G.657.A1:9.0±0.3μm; G.657.A2:8.6±0.4μm |

1550nm | G.652.D Normal:9.8±0.5μm; G.652.D Best:10.2±0.4μm; G.657.A1:10.2±0.4μm; G.657.A2:9.6±0.5μm |

4.6 Zero Dispersion Wavelength & Dispersion Coefficient

• Zero Dispersion Wavelength: 1300-1324nm (all variants)

• Dispersion Coefficient (1285-1339nm): G.652.D, G.657.A1/A2 ≤3.4ps/(nm·km)

4.7 Bending Loss

• 1550nm: 10 turns (15mm radius) ≤0.25dB; 100 turns (25mm radius) ≤0.03dB; 1 turn (10mm radius) ≤0.75dB; 1 turn (7.5mm radius) ≤0.2dB; 100 turns (30mm radius) ≤0.05dB

• 1625nm: 10 turns (15mm radius) ≤1.0dB; 1 turn (10mm radius) ≤1.5dB; 1 turn (7.5mm radius) ≤0.5dB

4.8 Point Discontinuity

• 1310nm & 1550nm: ≤0.05dB (all fibers)

5. Dimensions

Parameter | Specification |

Cladding Diameter | G.652.D Normal:125±0.7μm; G.652.D Best/G.657.A1/A2:125±0.5μm |

Core/Cladding Concentricity Error | G.652.D Normal: ≤0.5μm; G.652.D Best/G.657.A1/A2: ≤0.4μm |

Cladding Non-circularity | G.652.D Normal: ≤1.0%; G.652.D Best/G.657.A1/A2: ≤0.7% |

Coating Diameter | G.652.D (Normal/Best):245±5μm; G.657.A1/A2:242±5μm |

Coating/Cladding Concentricity Error | G.652.D (Normal/Best): ≤12μm; G.657.A1/A2: ≤8μm |

6. Mechanical Characteristics

• Fiber Strain: ≥1%

• Fiber Load: ≥9N

• Stress: ≥100kpsi

• Dynamic Stress Corrosion Susceptibility Factor: ≥20 (unaged & aged: 30 days @85°C, 85% R.H.)

• Coating Strip Force (Peak Value): 1.3-8.9N

• Fiber Curl: ≥4m

• Max. Installation Tension: 2400N (all core configurations)

• Min. Bending Radius: Without Tension - 10.0×Cable Diameter; Under Maximum Tension - 20.0×Cable Diameter

7. Environmental Characteristics

Test Condition | Attenuation Requirement (1310nm/1550nm) |

Dry Heat Aging (30 days @85°C) | ≤0.05dB/km / ≤0.05dB/km |

Accelerated Aging (30 days @85°C, 85% R.H.) | ≤0.05dB/km / ≤0.05dB/km |

Temperature Cycling | ≤0.05dB/km / ≤0.05dB/km |

Water Soak (30 days @23°C) | ≤0.05dB/km / ≤0.05dB/km |

8. Test Standards & Acceptance Criteria

Test Item | Test Method | Acceptance Requirements |

Tensile Strength | IEC 794-1-E1; 5000N load over 50m cable | Loss change ≤0.1dB (1550nm); No fiber break/sheath damage |

Crush Test | IEC 60794-1-E3; 3000N load over 100mm cable (≥1min) | Loss change ≤0.1dB (1550nm); No fiber break/sheath damage |

Impact Test | IEC 60794-1-E4; 5 points×5 times; 4.5Nm energy; 12.5mm hammerhead radius; 2s/cycle | Loss change ≤0.1dB (1550nm); No fiber break/sheath damage |

Repeated Bending | IEC 60794-1-E6; 20×OD bending diameter; 250N load; 3s/cycle×30 cycles | Loss change ≤0.1dB (1550nm); No fiber break/sheath damage |

Torsion | IEC 60794-1-E7; 1m length; 150N load; ±90° twist; 1min/cycle×10 cycles | Loss change ≤0.1dB (1550nm); No fiber break/sheath damage |

Water Penetration | IEC 60794-1-F5B; 3m sample submerged in 1m water for 24h | No water leakage |

Temperature Cycling | IEC 60794-1-F1; +20→-20→+20→+40°C; 24h/step×2 cycles | Loss change ≤0.1dB (1550nm); No fiber break/sheath damage |

Compound Flow | IEC 60794-1-E14; 30cm sample @70±2°C for 24h | No compound flow |

Sheath High Voltage Test | Online test (9kV, dependent on sheath thickness) | No sheath breakdown |

9. Marking & Color Code

9.1 Sheath Marking

• Content: [Cable type] [N*cores] G.652D [Manufacture year] [XXXXm]

• Print Interval: Every 1 meter

• Color: White

• Notes: Occasional unclear length marking permitted if neighboring markings are clear; Cable ends sealed with heat shrinkable caps

9.2 Fiber & Binder Color Code (EIA/TIA 598B)

• Fiber Colors: Blue (NO.1), Orange (NO.2), Green (NO.3), Brown (NO.4), Gray (NO.5), White (NO.6), Red (NO.7), Black (NO.8), Yellow (NO.9), Violet (NO.10), Pink (NO.11), Aqua (NO.12)

10. OEM Customization

• Core Count: 12,24,48,96,120,144 cores

• Design: 3+2+1 (12-core); 1+4+1 (24-core,48-core, etc.)

• Material Options: Central Strength Member (FRP/Steel Wire); Loose Tube (PBT); Filler (PP); Outer Sheath (HDPE)

• Adjustable Parameters: Jacket thickness, cable diameter, length per spool, marking content

11. Compliance Standards

ITU-T Rec. G.657A, ISO9001, IEC 60794, ICEA-596, GR-409, YD/T 1997-2009, EIA/TIA 598B

Product Advantage

-

1

Exceptional Optical Performance: Features low attenuation (≤0.22dB/km @1550nm for G.652.D) and minimal PMD (≤0.1ps/√km), ensuring reliable long-distance signal transmission with superior integrity.

-

2

Robust Mechanical Durability: Reinforced with GFRP central strength member and Aramid Yarns, offering high tensile strength (≥5000N load resistance) and excellent crush/impact resistance, suitable for harsh installation environments.

-

3

Superior Environmental Adaptability: Operates in a wide temperature range (-40°C to +70°C) and withstands humidity, water exposure, and temperature cycling with negligible attenuation change (≤0.05dB/km), ensuring stability in extreme climates.

-

4

Flexible Configuration Options: Supports multiple fiber counts (6-288 fibers) and customizable designs (loose tube diameter, jacket thickness, span lengths up to 150m), adapting to diverse project requirements.

-

5

Reliable Water Blocking & Protection: Integrated water-blocking tape, gel-filled tubes, and sealed ends prevent moisture ingress, while HDPE outer jacket provides UV and corrosion resistance for long service life.

-

6

Compliance with Global Standards: Meets ITU-T, IEC, ISO9001, and YD/T specifications, ensuring compatibility with existing networks and adherence to industry quality and performance benchmarks.

Home

Home