6|8|12 Cores G.652.D Fibers

Cable Type: 6/8/12-core ADSS cable with G.652.D single-mode fiber, double PE jacket.

Key Specs: Max span 200-500m, 110kv max voltage, 25m/s wind resistance (0mm ice load).

Optical Performance: Attenuation ≤0.35dB/km @1310nm, ≤0.22dB/km @1550nm; PMD ≤0.20ps/√km.

Construction: PBT loose tube, GFRP central strength member, Aramid yarn reinforcement, water-blocking design.

Mechanical Traits: Tensile strength ≥5000N, min bending radius 10×cable diameter (no tension); -40°C to +70°C operating temp.

Compliance: Meets ITU-T G.652.D, IEC 60794, ISO9001, EIA/TIA 598B standards.

Packaging: 3km/4km per wooden spool (Φ1100×750mm), sealed ends, marked every 1m.

Customization: Core counts (up to 288), tube configs, sheath thickness customizable.

- Product Description

- Specification

- Product Advantage

Product Description

1. Product Overview

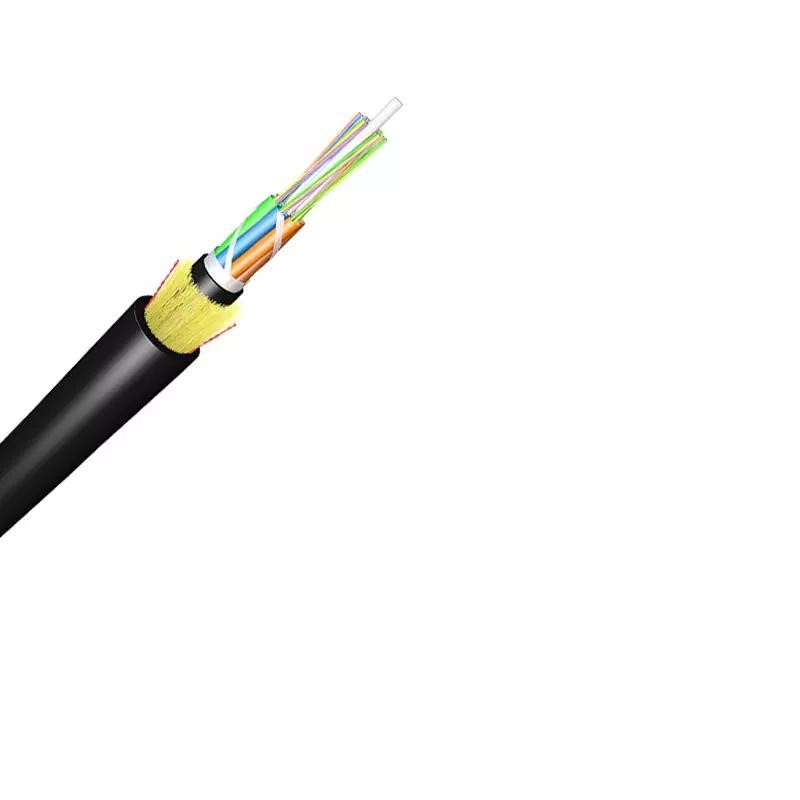

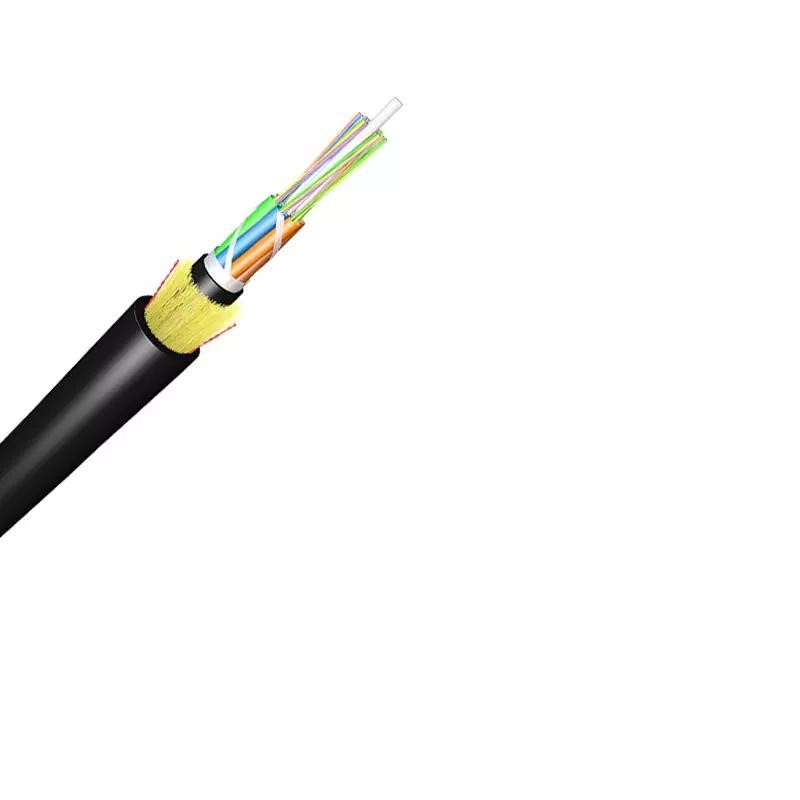

All-dielectric self-supporting (ADSS) cable with 6/8/12 cores of G.652.D single-mode optical fiber, featuring a double jacket PE sheath. Designed for outdoor use with excellent mechanical strength, environmental resistance, and optical performance, suitable for long-distance signal transmission in various climates.

2. Key Parameters

• Max Span: 200-500m

• Max Applied Voltage: 110kv

• Weather Resistance: 25m/s wind speed, 0mm ice load

• Temperature Range: -40°C to +70°C (operating); -20°C to +60°C (installation); -40°C to +70°C (transport & storage)

• Length per Spool: 3km or 4km (±2% tolerance)

• Cable Outer Diameter: 10.7±0.5mm

• Cable Weight: 85±5kg/km

Specification

3. Construction Details

Component | Specification |

Optical Fiber | G.652.D UV fiber; Attenuation: ≤0.35dB/km @1310nm, ≤0.22dB/km @1550nm |

Tube Filling Compound | Water-blocking & moisture-proof thixotropic gel |

Loose Tube | PBT material, 1.8-2.0mm outer diameter |

Filler | FRP (1.8mm), LDPE/PP material |

Central Strength Member | GFRP (1.8mm), glass fiber reinforced plastic rod |

Water Blocking Tape | 0.28mm thickness |

Binder | 2 wires of polyester yarns |

Ripcords | 2 wires |

Dielectric Strength Member | Aramid Yarns (KEVLAR K49-3000D) |

Inner Jacket | HDPE/MDPE, 0.9-1.0mm thickness |

Outer Jacket | HDPE/MDPE, 1.6-2.0mm thickness |

4. Optical Characteristics

4.1 Fiber Types & Attenuation

Fiber Type | Attenuation (dB/km) @850nm | @1300nm | @1310nm | @1550nm |

G.652.D (SM) | - | - | ≤0.36 | ≤0.22 |

G.655 (SM) | - | - | ≤0.40 | ≤0.23 |

50/125μm (MM) | ≤3.0 | ≤1.0 | - | - |

62.5/125μm (MM) | ≤3.0 | ≤1.0 | - | - |

4.2 Bandwidth (Multimode)

• 50/125μm: ≥500 MHz·km @850nm, ≥1000 MHz·km @1300nm

• 62.5/125μm: ≥200 MHz·km @850nm, ≥600 MHz·km @1300nm

4.3 Polarization Mode Dispersion (PMD)

• Individual fiber: ≤0.20 ps/√km (G.652.D, G.655)

• Design Link Value (M=20, Q=0.01%): ≤0.10 ps/√km (G.652.D, G.655)

4.4 Transmission Bands

Band | Wavelength Range (nm) | Frequency Range (THz) | Application |

O Band | 1260-1360 | 237.9-220.4 | Multimode systems |

E Band | 1360-1460 | - | Less common (high attenuation) |

S Band | 1460-1530 | 205.3-195.9 | Passive Optical Networks (PON) |

C Band | 1530-1565 | 195.9-191.6 | Long-haul transmission (min attenuation) |

L Band | 1565-1625 | 191.6-184.5 | Extended reach, high-capacity networks |

U Band | 1625-1675 | 184.5-179.0 | Network monitoring |

4.5 Additional Optical Parameters

• Mode Field Diameter (MFD): Compliant with ITU-T Rec. G.652/G.657

• Point Discontinuity: ≤0.05 dB @1310nm & 1550nm (all fibers)

5. Dimensional Specifications

Parameter | G.652.D Normal | G.652.D Best | G.657.A1 | G.657.A2 |

Cladding Diameter (μm) | 125±0.7 | 125±0.5 | 125±0.5 | 125±0.5 |

Core/Cladding Concentricity Error (μm) | ≤0.5 | ≤0.4 | ≤0.4 | ≤0.4 |

Cladding Non-Circularity (%) | ≤1.0 | ≤0.7 | ≤0.7 | ≤0.7 |

Coating Diameter (μm) | 245±5 | 245±5 | 242±5 | 242±5 |

Coating/Cladding Concentricity Error (μm) | ≤12 | ≤12 | ≤8 | ≤8 |

6. Mechanical Characteristics

• Fiber Strain: ≥1%

• Fiber Load: ≥9 N

• Stress Resistance: ≥100 kpsi

• Dynamic Stress Corrosion Susceptibility Factor: ≥20 (unaged & aged: 30 days @85°C, 85% R.H.)

• Coating Strip Force (Peak Value): 1.3-8.9 N

• Fiber Curl: ≥4 m

• Max Installation Tension: 2400 N

• Min Bending Radius: 10×cable diameter (without tension); 20×cable diameter (under max tension)

7. Environmental Characteristics

Test Condition | Attenuation Change (dB/km) @1310nm | @1550nm |

Dry Heat Aging (30 days @85°C) | ≤0.05 | ≤0.05 |

Accelerated Aging (30 days @85°C, 85% R.H.) | ≤0.05 | ≤0.05 |

Temperature Cycling | ≤0.05 | ≤0.05 |

Water Soak (30 days @23°C) | ≤0.05 | ≤0.05 |

8. Mechanical & Environmental Tests (Compliance Standards)

Test Item | Method | Acceptance Criteria |

Tensile Strength | IEC 794-1-E1; 5000N load on 50m cable | ≤0.1dB loss @1550nm; no fiber break/sheath damage |

Crush Test | IEC 60794-1-E3; 3000N load on 100mm cable (≥1min) | Same as above |

Impact Test | IEC 60794-1-E4; 5 points×5 impacts, 4.5Nm energy | Same as above |

Repeated Bending | IEC 60794-1-E6; 20×OD bend, 250N load, 30 cycles | Same as above |

Torsion | IEC 60794-1-E7; 1m length, 150N load, ±90° twist (10 cycles) | Same as above |

Water Penetration | IEC 60794-1-F5B; 3m sample in 1m water (24h) | No water leakage |

Temperature Cycling | IEC 60794-1-F1; +20→-20→+20→+40°C (2 cycles, 24h/step) | Same as tensile strength |

Compound Flow | IEC 60794-1-E14; 30cm sample @70±2°C (24h) | No compound flow |

Sheath High Voltage Test | Online test (9kV, dependent on sheath thickness) | No sheath breakdown |

9. Standards Compliance

• ITU-T Rec. G.657A, G.652.D

• ISO9001

• IEC 60794

• ICEA-596

• GR-409

• YD/T 1997-2009

• EIA/TIA 598B (fiber/binder color code)

10. Fiber & Cable Marking

• Fiber Colors (12 chromatography): Blue, Orange, Green, Brown, Gray, White, Red, Black, Yellow, Violet, Aqua, Pink

• Cable Marking: Printed every 1m, including cable type, core count, G.652D specification, manufacture year, and length. Color: white. Both ends sealed with heat-shrinkable caps.

11. Packing Specifications

• Spool Type: Wooden drum (Φ1100×750mm)

• Packing: Cable reeled on wooden drum, covered with plastic buffer sheet, sealed with wooden battens.

• Reserved Length: ≥1m inside end for testing.

• Drum Marking: Includes cable type, size, length, gross/net weight, manufacture year/month, and handling cautions. "MADE IN CHINA" marked.

12. Customization (OEM)

• Core Count Options: 12,24,48,72,96,144,288 fibers

• Loose Tube Configuration: Customizable (e.g., 1x6, 2x6 for 6 fibers; 4x12, 6x12 for 12 fibers)

• Outer Diameter Adjustment: 8.0-11.0mm (customizable)

• Central Strength Member: Optional FRP/steel wire (diameter: 1.0-3.7mm)

• Outer Sheath Thickness: 0.8-2.0mm (dependent on core count)

Product Advantage

-

1

Excellent Optical Transmission: Low attenuation (≤0.35dB/km @1310nm, ≤0.22dB/km @1550nm) and minimal PMD ensure stable long-distance signal transmission with high fidelity.

-

2

Robust Mechanical Strength: Reinforced with GFRP central member and Aramid yarns, offering strong tensile resistance (≥5000N) and durability against bending, crushing, and torsion.

-

3

Superior Environmental Adaptability: Wide operating temperature range (-40°C to +70°C) and water-blocking design resist harsh conditions like extreme weather, humidity, and water infiltration.

-

4

Reliable All-Dielectric Design: Double PE jacket and dielectric materials support 110kv max applied voltage, ideal for power system-related installations with safety and insulation.

-

5

Flexible Customization: Adjustable core counts (up to 288), loose tube configurations, and sheath specifications meet diverse project requirements for span and capacity.

-

6

Compliant & Quality-Assured: Adheres to global standards (ITU-T, IEC, ISO9001) with rigorous mechanical/environmental tests, ensuring consistent performance and reliability.

Home

Home