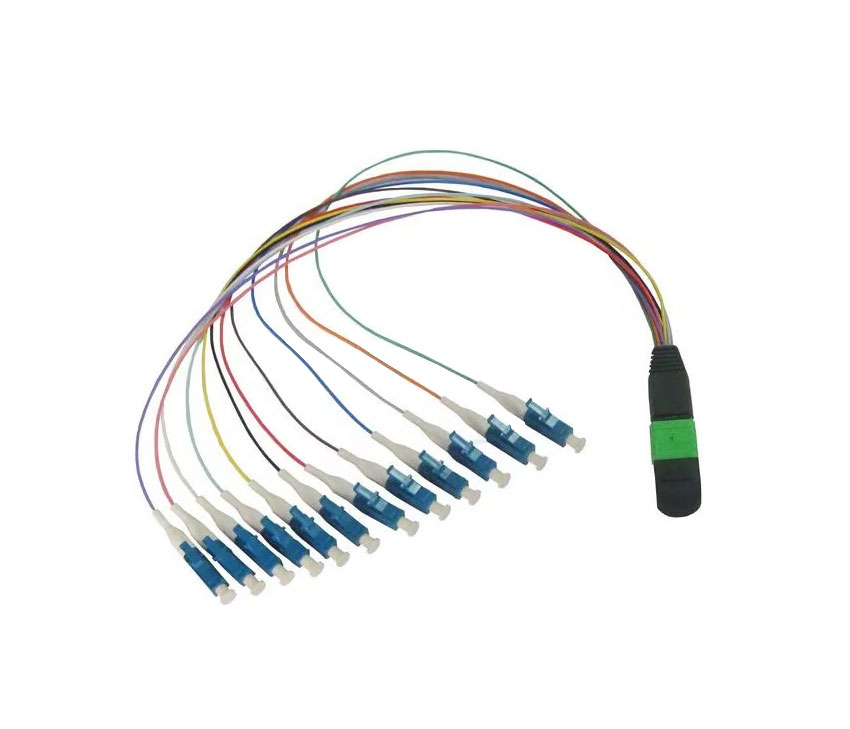

Multi Mode MPO to LC Fiber Cable, 50/125μm MPO MTP Harness Cable

Fiber type: Multi-mode with 50/125μm core/cladding diameter

Connector configuration: MPO (male/female optional) to duplex LC

Key performance: Low insertion loss (≤0.3dB MPO, ≤0.2dB LC typical), high return loss (≥45dB UPC)

Construction: UV-cured acrylate buffer, aramid yarn strength member, flame-retardant jacket (PVC/LSZH)

Operating specs: Wavelength 850-1300nm, temp -20°C to +70°C, ≥1000 mating cycles

Mechanical features: Tensile strength ≥150N (installation), flexible bending radius (10× static/20× dynamic cable diameter)

Applications: High-speed data transmission in optical communication systems (interface conversion)

Quality assurance: 100% factory testing for insertion/return loss and fiber continuity

- Product Description

- Specification

- Product Advantage

Product Description

1. Overview

This technical specification defines the key requirements, performance parameters, installation guidelines, and dimensional characteristics of the multi-mode MPO (Multi-Fiber Push-On) to LC fiber optic cable with a 50/125μm fiber core/cladding diameter. The cable is designed for high-speed data transmission in optical communication systems, facilitating reliable signal conversion and transmission between MPO and LC interfaces.

Specification

2. Fiber Core Specifications

Parameter | Specification |

Fiber Type | Multi-mode optical fiber |

Core/Cladding Diameter | 50μm / 125μm |

Numerical Aperture (NA) | Conforms to industry standard for 50/125μm multi-mode fiber (typically 0.200 ± 0.015) |

Attenuation | Maximum attenuation at 850nm: ≤ 3.5 dB/km; Maximum attenuation at 1300nm: ≤ 1.0 dB/km (at 23°C ± 2°C) |

Bandwidth | Modal Bandwidth (OM3/OM4 compliant, as applicable):<br>- OM3: ≥ 2000 MHz·km at 850nm<br>- OM4: ≥ 4700 MHz·km at 850nm |

3. Cable Construction

• Fiber Count: Configurable based on application requirements (common configurations: 8-fiber, 12-fiber, 24-fiber, etc., corresponding to MPO connector channel count)

• Buffer Coating: UV-cured acrylate, diameter: 250μm

• Strength Member: Aramid yarn (Kevlar) for tensile reinforcement, ensuring mechanical stability during installation and operation

• Cable Jacket: Flame-retardant PVC or LSZH (Low Smoke Zero Halogen) material, resistant to abrasion, moisture, and environmental aging

• Jacket Color: Standard color (e.g., aqua for OM3, lime for OM4) or customizable based on system requirements

4. Connector Specifications

4.1 MPO Connector

• Type: Male/female (configurable), push-on latching mechanism

• Fiber Polishing: Physical Contact (PC) or Ultra Physical Contact (UPC)

• Insertion Loss: ≤ 0.3 dB (typical); ≤ 0.5 dB (maximum)

• Return Loss: ≥ 45 dB (UPC); ≥ 55 dB (APC, if applicable)

• Operating Temperature: -20°C to +70°C

• Durability: ≥ 1000 mating cycles without significant performance degradation

4.2 LC Connector

• Type: Duplex LC (SC/PC compatible), snap-in latching mechanism

• Fiber Polishing: PC or UPC

• Insertion Loss: ≤ 0.2 dB (typical); ≤ 0.3 dB (maximum)

• Return Loss: ≥ 45 dB (UPC); ≥ 60 dB (APC, if applicable)

• Operating Temperature: -20°C to +70°C

• Durability: ≥ 1000 mating cycles without significant performance degradation

5. Electrical and Optical Performance

• Operating Wavelength Range: 850nm - 1300nm (optimized for multi-mode transmission)

• Maximum Operating Voltage: Not applicable (passive optical component)

• Insulation Resistance: ≥ 10^12 Ω (between fiber and connector housing, at 500V DC)

• Cross-Talk: Negligible (compliant with IEC/ANSI standards for multi-mode fiber systems)

6. Mechanical Properties

• Tensile Strength: Minimum 150 N (during installation); Minimum 50 N (long-term operation)

• Crush Resistance: ≥ 1000 N/100mm (for 1 minute, no fiber damage or performance degradation)

• Bending Radius: Static (installation): ≥ 10 × cable diameter; Dynamic (operation): ≥ 20 × cable diameter

• Twist Resistance: ± 180° per meter, no permanent damage or performance loss

7. Environmental Requirements

• Operating Temperature: -20°C to +70°C

• Storage Temperature: -40°C to +85°C

• Humidity: 0% - 95% (non-condensing)

• Flame Retardancy: Compliant with UL 94 V-0 or IEC 60332-1-2

• Chemical Resistance: Resistant to common industrial chemicals, oils, and solvents

8. Installation Guidelines

• The cable should be routed away from sharp edges, high-temperature sources, and strong electromagnetic interference (EMI) environments.

• Avoid excessive pulling, bending, or twisting during installation to prevent fiber breakage or performance degradation.

• Connector mating should be performed with clean, dry connectors; use approved fiber cleaning tools to remove dust or debris before mating.

• The cable should be secured with appropriate cable ties or clamps, ensuring no excessive pressure on the cable jacket or connectors.

• Follow standard fiber optic installation practices for termination, splicing (if required), and testing.

9. Testing and Quality Assurance

• Each cable undergoes 100% factory testing for insertion loss, return loss, and visual inspection of connectors and fiber continuity.

• Testing equipment is calibrated to IEC/ANSI traceable standards.

• Visual inspection includes checking for connector scratches, contamination, and proper fiber alignment.

• Random sampling for mechanical and environmental performance testing is conducted per quality control procedures.

10. Dimensional Reference (Typical)

• Cable Outer Diameter: Dependent on fiber count and jacket material (typical range: 3.0mm - 6.0mm)

• MPO Connector Dimensions: Compliant with IEC 61754-7 standard (length: ~65mm, width: ~12mm, height: ~8mm)

• LC Connector Dimensions: Compliant with IEC 61754-20 standard (length: ~24mm, width: ~12mm, height: ~8mm)

• Cable Length: Customizable (standard lengths: 1m, 2m, 3m, 5m; maximum length subject to attenuation limits)

Product Advantage

-

1

Low-loss optical performance: Ensures reliable signal transmission with minimal insertion loss and high return loss.

-

2

Robust mechanical design: Aramid yarn reinforcement and durable jacket enable excellent tensile/crush resistance for long-term reliability.

-

3

Versatile compatibility: Supports MPO-LC interface conversion and OM3/OM4 multi-mode fibers for flexible system integration.

-

4

Wide operating range: Functions stably in -20°C to +70°C temperature and high-humidity environments, adapting to diverse scenarios.

-

5

Long service life: ≥1000 mating cycles and wear-resistant connectors extend product durability.

-

6

Rigorous quality guarantee: 100% factory-tested for optical and physical performance, ensuring consistent quality.

Home

Home