Fiber Distribution Hub

The backboard connectivity solutions shall be designed as customer-configurable distribution platforms, suitable for installation in street cabinets and other outdoor or indoor cabinet environments.

The design shall facilitate efficient routing, management, and termination of incoming and outgoing fiber optic cables, as well as blown fibers (where applicable).

For FDH configurations incorporating fiber optic splitters, the design shall provide dedicated, protected mounting positions for splitters and ensure proper fiber routing between input, splitter, and output ports.

All components shall be constructed with materials resistant to environmental factors such as moisture, dust, temperature variations, and UV radiation (for outdoor applications) in accordance with Telecordia GR-63-CORE.

- Product Description

- Specification

- Product Advantage

Product Description

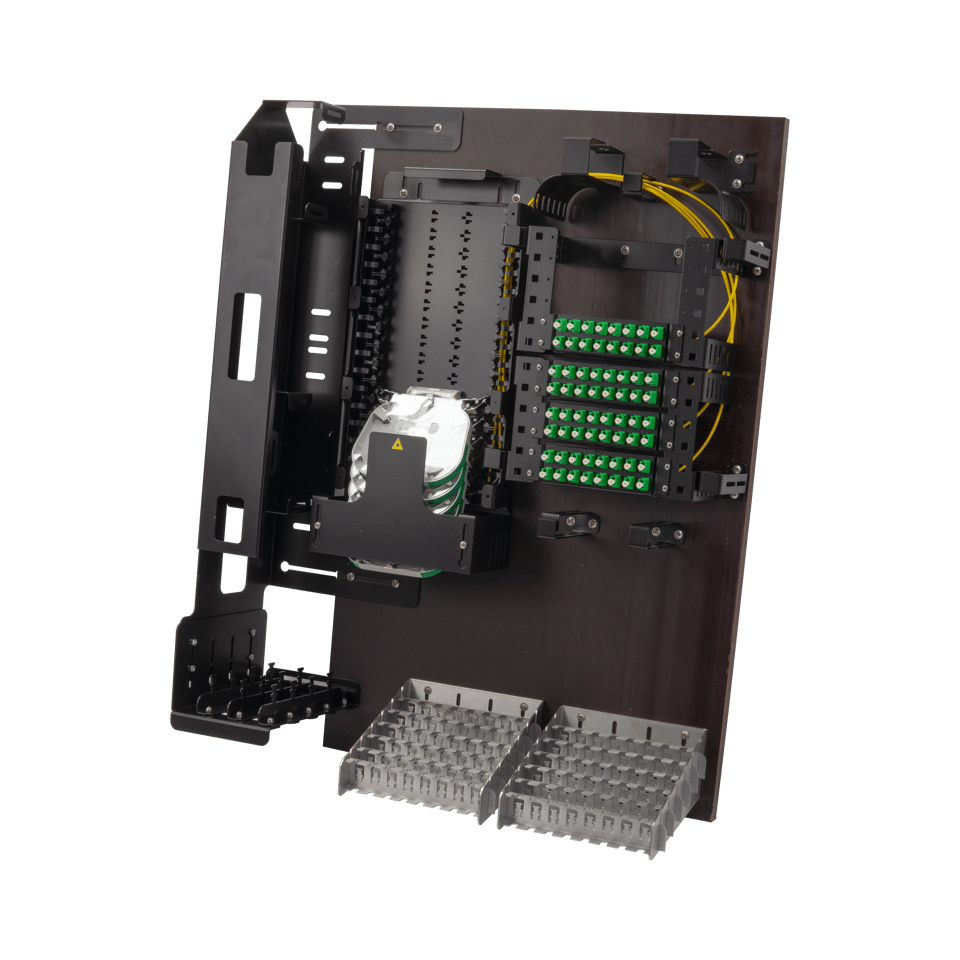

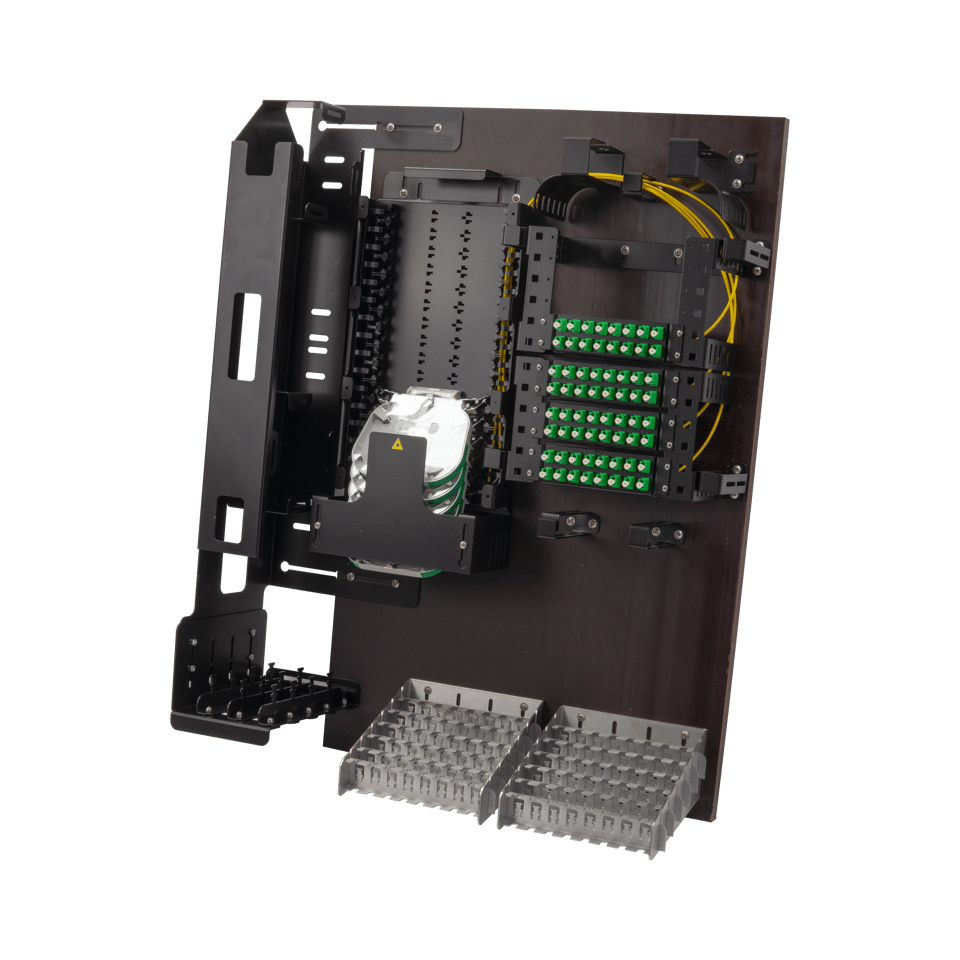

This technical specification defines the requirements, performance criteria, and compliance standards for fiber backboard connectivity solutions and associated accessories. These solutions are designed to enable the conversion of standard cabinets into functional Fiber Access Terminals (FATs) or Fiber Distribution Hubs (FDHs) for fiber optic network deployments. The specification is applicable to passive fiber distribution systems, including those used in Fiber-to-the-Home (FTTH) networks with Passive Optical Network (PON) topology, and adheres to the relevant provisions of IEC (International Electrotechnical Commission) and Telecordia standards.

Specification

3. General Requirements

3.1 Design Principles

• The backboard connectivity solutions shall be designed as customer-configurable distribution platforms, suitable for installation in street cabinets and other outdoor or indoor cabinet environments.

• The design shall facilitate efficient routing, management, and termination of incoming and outgoing fiber optic cables, as well as blown fibers (where applicable).

• For FDH configurations incorporating fiber optic splitters, the design shall provide dedicated, protected mounting positions for splitters and ensure proper fiber routing between input, splitter, and output ports.

• All components shall be constructed with materials resistant to environmental factors such as moisture, dust, temperature variations, and UV radiation (for outdoor applications) in accordance with Telecordia GR-63-CORE.

3.2 Mechanical Requirements

• The backboard structure shall have a minimum load-bearing capacity to support the maximum intended number of fiber optic connectors, splice trays, splitters, and associated cabling, without deformation or structural failure.

• Mounting points for the backboard within the cabinet shall comply with standard cabinet mounting hole patterns or provide adaptable mounting brackets to ensure compatibility with a wide range of cabinet types.

• All edges and surfaces shall be free of sharp burrs or projections to prevent damage to fiber cables or injury to installation personnel.

• The overall dimensions of the backboard shall be optimized for space efficiency within standard cabinets, while allowing sufficient access for installation, maintenance, and reconfiguration.

3.3 Environmental Performance

• Operating Temperature Range: -40°C to +65°C (in compliance with Telecordia GR-63-CORE Class 4 for outdoor applications)

• Storage Temperature Range: -40°C to +85°C

• Relative Humidity: 5% to 100% (non-condensing)

• Ingress Protection: Minimum IP54 rating (per IEC 60529) for components exposed to external environments

• Resistance to UV Radiation: Compliant with IEC 60068-2-5 Xenon arc testing requirements

4. Optical Performance Requirements

4.1 Fiber Compatibility

• The solutions shall support both single-mode (SM) and multi-mode (MM) optical fibers, in accordance with IEC 60793-2 Series.

• Single-mode fiber compatibility: ITU-T G.652.D, G.657.A1, G.657.A2, G.657.B3

• Multi-mode fiber compatibility: IEC 60793-2-10 OM3, OM4

4.2 Insertion Loss and Return Loss

• For fiber optic connector interfaces integrated into the backboard:

○ Insertion Loss (IL): ≤ 0.3 dB (maximum) for single-mode fibers; ≤ 0.2 dB (maximum) for multi-mode fibers (per IEC 61300-3-3)

○ Return Loss (RL): ≥ 50 dB (minimum) for single-mode fibers; ≥ 35 dB (minimum) for multi-mode fibers (per Telecordia GR-1209-CORE)

• For fiber optic splitters (when integrated):

○ Insertion Loss: Shall comply with the applicable splitter ratio requirements specified in IEC 61753-1 and Telecordia GR-1221-CORE, with maximum IL values as defined for the specific splitter configuration (e.g., 1x8, 1x16, 1x32).

○ Uniformity of Split: ≤ 0.8 dB (maximum) for all output ports of the splitter.

○ Return Loss: ≥ 50 dB (minimum) for input and output ports (single-mode).

4.3 Fiber Protection

• All fiber routing paths on the backboard shall provide sufficient bend radius protection, with a minimum bend radius of 10 mm for single-mode fibers and 15 mm for multi-mode fibers (during installation) and 7.5 mm for single-mode fibers and 10 mm for multi-mode fibers (in final position), in compliance with IEC 60793-1.

• Splice trays (if included) shall provide environmental protection for fiber splices, with splice loss performance meeting IEC 61300-3-4 requirements (maximum splice loss ≤ 0.1 dB for single-mode, ≤ 0.2 dB for multi-mode).

5. Compliance and Testing

5.1 Compliance Verification

• All components of the backboard connectivity solution shall be tested and verified to comply with the requirements of the referenced IEC and Telecordia standards.

• A compliance certificate shall be provided for each product type, documenting the results of all applicable tests.

5.2 Test Methods

• Mechanical Testing:

○ Load-bearing test: Apply 1.5 times the maximum intended load to the backboard for 24 hours, verify no permanent deformation.

○ Vibration test: Comply with IEC 60068-2-6, 10 Hz to 500 Hz, 10 g acceleration (peak) for 2 hours per axis.

• Environmental Testing:

○ Temperature cycling: IEC 60068-2-14, -40°C to +65°C, 10 cycles, 1 hour dwell time at each extreme.

○ Humidity testing: IEC 60068-2-3, 93% relative humidity, +40°C, 10 days.

○ UV exposure: IEC 60068-2-5, 1000 hours, xenon arc lamp.

• Optical Testing:

○ Insertion loss and return loss: IEC 61300-3-3, using an optical power meter and light source (single-mode: 1310 nm, 1550 nm; multi-mode: 850 nm, 1300 nm).

○ Splitter performance: IEC 61753-1, using a swept-wavelength interferometer or optical spectrum analyzer.

6. Marking and Documentation

6.1 Marking

• Each backboard and major component shall be marked with the following information (excluding customer-specific part numbers or trade names):

○ Compliance symbols for IEC and Telecordia standards (e.g., "IEC 61300 Compliant", "Telecordia GR-1221 Compliant")

○ Environmental rating (e.g., "IP54", "-40°C to +65°C")

○ Fiber type compatibility (e.g., "SM G.652/G.657", "MM OM3/OM4")

○ Manufacturing date (year and month)

○ Serial number (unique identifier)

6.2 Documentation

• The following documentation shall be provided with each delivery:

○ Technical data sheet, including dimensions, weight, optical performance specifications, and environmental ratings.

○ Installation manual, providing step-by-step instructions for mounting the backboard, routing cables, and terminating fibers.

○ Compliance certificate, verifying adherence to the requirements of this specification and referenced standards.

○ Maintenance guidelines, including recommended inspection intervals and cleaning procedures for fiber optic interfaces.

7. Quality Assurance

• The manufacturing process shall be in accordance with ISO 9001 quality management system requirements.

• A quality control plan shall be implemented, including incoming inspection of raw materials, in-process testing of components, and final inspection of finished products.

• All products shall be subjected to 100% optical performance testing prior to shipment.

• A warranty period of at least 5 years shall be provided, covering defects in materials and workmanship under normal operating conditions.

Product Advantage

-

1

Compliance with Global Industry Standards

-

2

Versatile and Configurable Design

-

3

Superior Optical Performance

-

4

Robust Mechanical and Environmental Durability

-

5

Efficient Installation, Maintenance, and Cost-Effectiveness

-

6

Backed by a minimum 5-year warranty covering material and workmanship defects, providing long-term peace of mind and reducing total cost of ownership (TCO) for network operators.

Home

Home